Commercial Soundproofing London:

Timber Acoustic Doors / Mayfair, London – read more…

Client

Private Company, Mayfair, London

Project Brief

To design, manufacture and install acoustic doors, for a CEO’s private office, with a view to delivering a quieter, more confidential working environment.

To match the architectural design of the existing doors, as close as practicably possible.

To adhere to a strict installation schedule, so as to minimise disruption to the CEO and their supporting staff.

Methodology (in summary)

Site Survey:

A detailed site survey was carried out, to inspect the existing doors. The raised panels required particularly close attention, to gauge their precise pitch and elevation. The profile of the surrounding frames also needed to be identified.

The survey included sound insulation testing, which demonstrated that the existing doors provided, as a mean, 18 dB(A) airborne sound insulation, with a notable weakness at the meeting stile (due to a lack of airtightness).

As a point of reference, standard speech between two people, when measured from one metre away, typically registers at c.60 dB(A). As such, it could be asserted that the existing doors had a performance deficit of between 12 to 15 dB(A), allowing for the reduction of sound over distance and the prevailing ambient noise levels.

Design & Planning of Acoustic Doors:

Based on the data collected, *Rw 42 dB(A) timber acoustic doors were specified, to include a 30 minute fire rating.

Because acoustic doors are manufactured as flush units, the raised panels and frames needed to be retro-fitted, prior to the paint finish being applied. It was decided the paint finish would be sprayed on, to achieve a flawless finish – as such, all of the ironmongery, door furniture and locks were cut-in to the doors during their construction, i.e. to avoid heavy works to the doors, in their finished state.

*Rw is the weighted sound reduction in dB (decibels) and it describes the airborne sound insulating power of a building element. It is a laboratory-measured value, as defined in ISO717 Part 1.

Manufacture & Installation of Acoustic Doors:

Once manufactured, the acoustic door blanks were delivered to the spray finishers, where the following steps were taken:

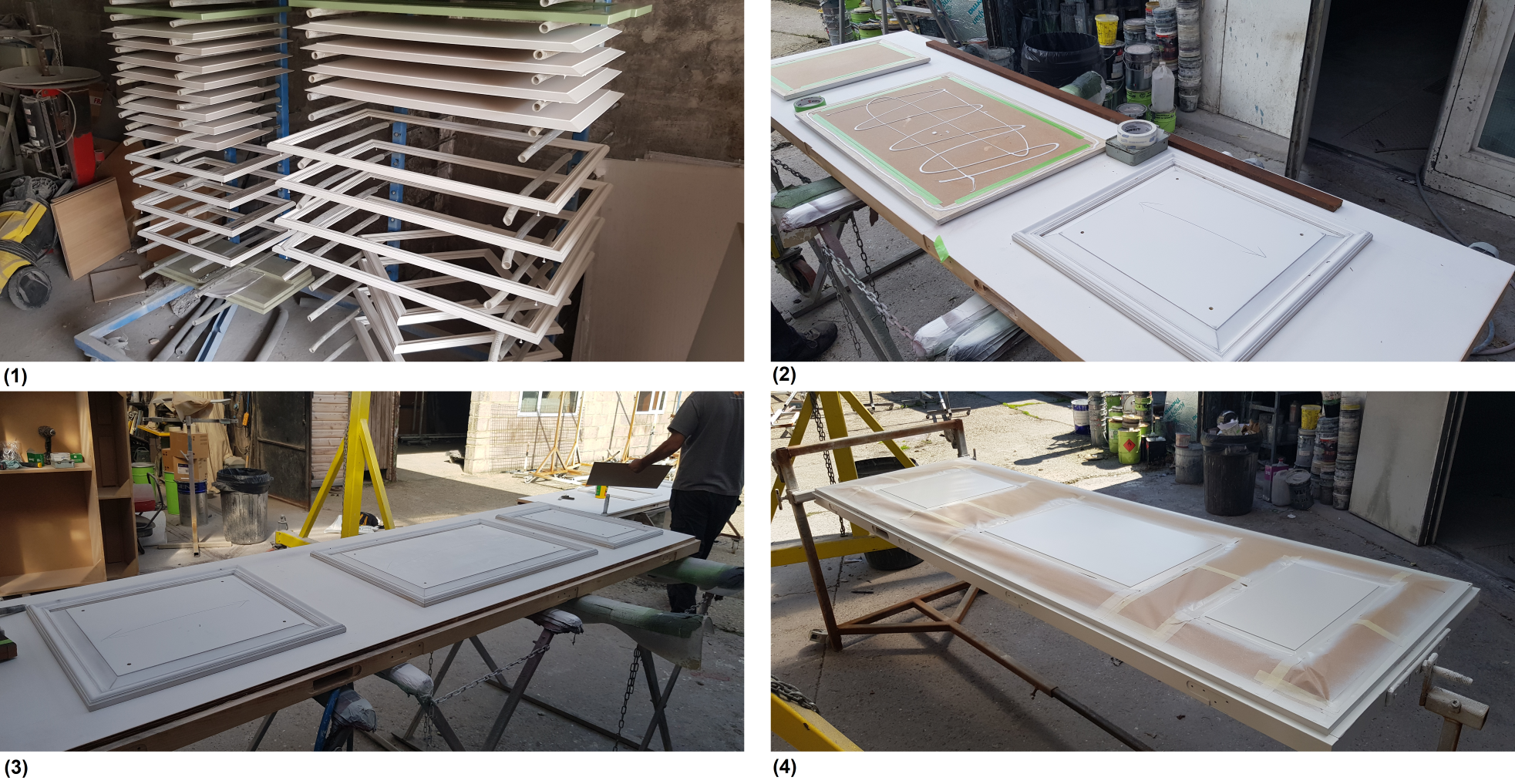

(1) Pre-made raised panels and frames primed, ready for mounting to acoustic door blanks.

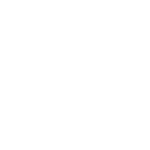

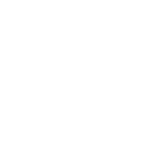

(2) & (3) Raised panels and frames mounted to acoustic door blanks – screwed, glued and secret nailed.

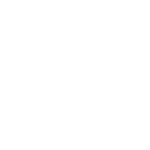

(4) Acoustic doors (with raised panels and frames affixed), filled, sanded, caulked and re-primed.

(5) Existing doors colour matched – black, with 65% sheen, approved by client.

(6) 1st black spray coat applied to acoustic doors, before final sand and finishing coat.

Once spray finished, the acoustic doors and frame were delivered to site, for installation, at which point the ironmongery, door furniture and locks were fitted (9), followed by general making-good around the frame and architraves.

Finally, a pre-completion sound test was conducted, demonstrating that the replacement acoustic doors provide, as a mean, 38 dB(A) airborne sound insulation – an upgrade of 20 dB(A), compared with the original doors; exceeding the essential performance criterion by 5 to 8 dB(A).

The image at the foot of the page compares the original doors (left) and the replacement acoustic doors (right).

Acoustic Doors (a general discussion about acoustical performance)

Essentially, acoustic doors / acoustical door treatments come in 3 performance / price tiers.

Tier 1 – Upgrading Existing Doors:

Acoustically upgrading existing doors is the most simple and economical approach, typically involving, where practicable, mass-loading and airtightness works.

Such applications, based on a cross-section of field test data, can upgrade the airborne sound insulating performance of existing doors by c. 10 to 14 dB(A).

Standard flush timber doors tend to provide in the order of 20 to 22 dB(A) airborne sound insulation, therefore, post-works, one can expect such doors to provide approximately 30 to 36 dB(A) airborne sound insulation.

The images below show a robust system, designed and installed by Mute Soundproofing®, for a luxury chalet in the French Alps. The existing internal timber doors were acoustically clad & sealed, critically, to match the surrounding aesthetic. Having been tested, pre-works, to provide just 15 dB(A) airborne sound insulation, the doors now provide 32 dB(A) airborne sound insulation. This 17 dB(A) upgrade significantly reduces inter-space sound passage, throughout the building.

Tier 2 – Timber Acoustic Doors:

Flush timber acoustic doors (and frames) can be specified up to Rw 48 dB(A) for a single leaf and Rw 46 dB(A) for a double leaf (with meeting stile), whilst glazed timber acoustic doors (and frames) can be specified up to Rw 43 dB(A), assuming a vision panel of < 0.25 m2.

Timber acoustic doors are available in a wide variety of paint and timber veneer finishes, as such they represent the most aesthetically versatile option.

Tier 3 – Steel Acoustic Doors:

Steel acoustic doors (and frames) can be specified up to Rw 63 dB(A). However, whilst steel acoustic doors clearly acoustically out-perform timber acoustic doors, their significant mass can be prohibitive within certain architectural environments – as such, a structural engineer should be consulted to assess their suitability. Moreover, their industrial appearance can preclude them from certain interior designs.

+44 (0) 20 3858 0833

+44 (0) 20 3858 0833 email

email